Today we want to share some recommendations for what spark plugs to run, in terms of spark plug electrode material, spark plug heat range, spark plug gap, and other options. These recommendations are meant for modified cars, from BPU to wild. The stock or parts store plugs are acceptable for a bone stock 3000GT or Dodge Stealth. Non turbo cars also tend to run just fine on stock platinum type plugs from Denso or NGK.

Spark Plug Materials

Spark plugs most commonly come in the following 3 materials:

- Iridium

- This is a precious metal that is laser welded and allows for a very fine electrode that can help reduce the requirements of your secondary ignition system, namely your coils. They are not without compromise though, they can be quite expensive, and rarely the electrode can break off on boosted or nitrous applications and this can damage your engine and turbo charger. Normally these should not be gapped.

- Platinum

- This is also a precious metal plug that is found in many oem applications, including the original spark plugs for the 3000GT and Dodge Stealth’s. They have a very long lifespan and can last from 60000 to 100000 miles.

- Copper

- These are a very affordable plug, a set of 6 is about $20.00. This allows them to be changed very frequently and you don’t have to worry so much about running rich while tuning ruining expensive Iridum or Platinum plugs. They are also easy to gap and do well in high boost environments. For most performance applications we recommend running a copper plug.

Heat Ranges

- Heat Range 6

- This is the stock heat range for a turbo car and is suitable for stock or very mildly modified cars. It will not foul easily and if you have a car that burns some oil these will last the longest without misfires.

- Heat Range 7

- We specifically recommend NGK 7 Series Plugs for this heat range. This is a good range for most BPU cars. 10 – 15 PSI on pump gas.

- Heat Range 8

- Once we start getting over 15 PSI or running e85 or methanol we’d recommend an 8 series plug. We personally use the NGK 8 Series Plugs for this. It is hard to put a precise upper limit on the power or boost you can run with these, but once we go colder than an 8 series plug you will have to be careful to have your tune not too rich and also run the car at WOT often to clean the plugs.

- Heat Range 9

- If you are running a maximum effort E85 or race gas car you may consider heat range 9 plugs like the NGK 9 Series.

- Heat Range 10

- With a maximum effort E85, race gas, or nitrous car you may want to step up to a heat range 10 plug like the NGK 10 Series. These may especially be needed if you do multiple gear pulls or top speed runs. They will probably tend to foul if you do a lot of cold starts or short trips. More suitable if you drive your car like your racing.

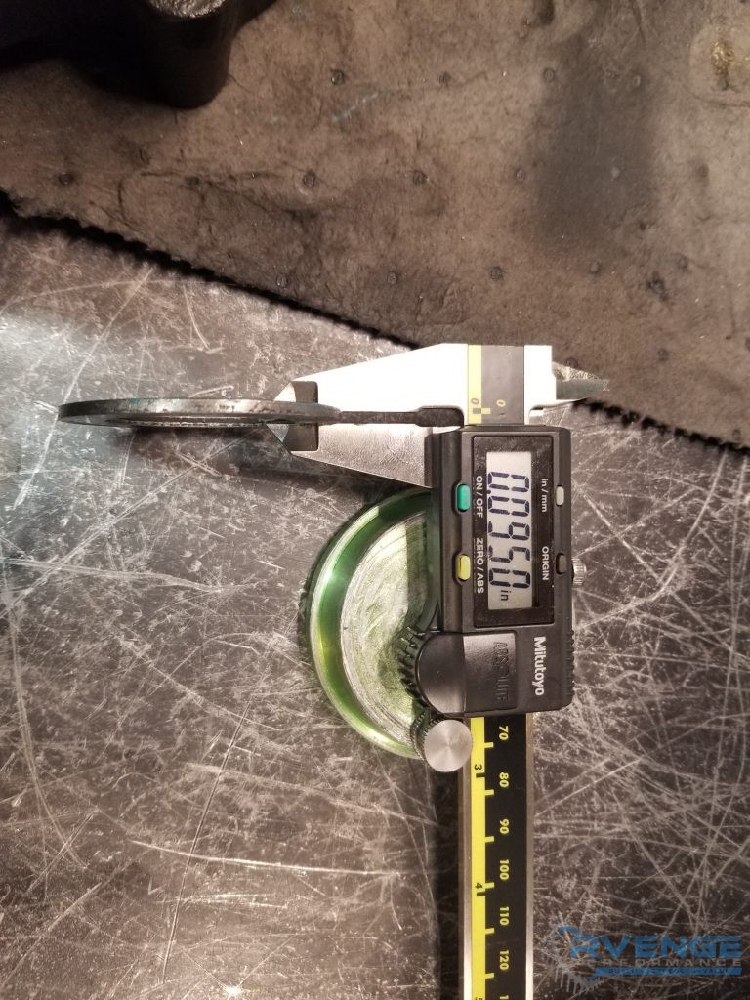

Spark Plug Gaps

The stock gap is in the .040 range and this is just too wide for our ignition system and running a lot of boost. There is some theory that you should run the largest gap possible, but we have not seen a lot of empirical evidence supporting this. It is very important that your ignition pulls cleanly. A misfire at high power can actually damage your rod bearings from the uneven load on the engine. Once you have found the point where you have no misfires you may want to gap down an additional .002 for wear and reliability.

- .030″ Gap

- Good all around gap, should not see spark blowout unless your ignition system is weak or running over 20 PSI.

- .026″ – .028″

- With a healthy ignition this is good for 20-25 PSI.

- .022″ – .026″

- Typically good for 25 to 30 PSI.

- .020″ or less.

- This is good if your ignition system is a little weak or you are running a lot of boost. As you get under .020″ you may eventually start to see some decreased idle quality, but it may be needed to light off high power setups, especially high boost E85 setups.

Resistor vs Non-Resistor Plugs

Resistor plugs typically have a 5 OHM resistor in them. This is done to prevent electrical or radio / RF interference. To get the most out of your ignition system it does seem a little bit unproductive to install a resistor in your ignition system though.

There are many systems, such as ignition amplifiers, or the AEM Series 2 ECU that recommend resistor plugs, but in real life we’ve never seen an issue running non resistor plugs. If you tend to listen to AM radio or have some weird eletronic glitches you may want to give resistor plugs a try, but we’d try the non resistor ones first.

.png)

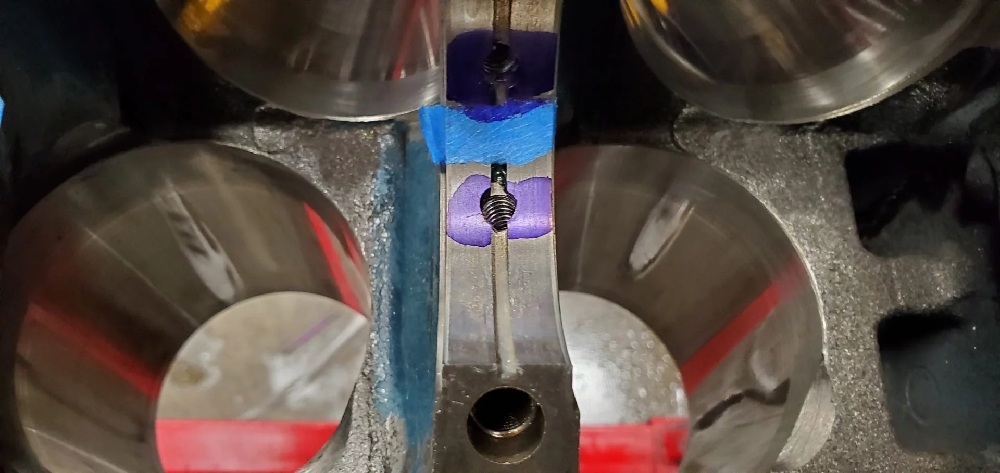

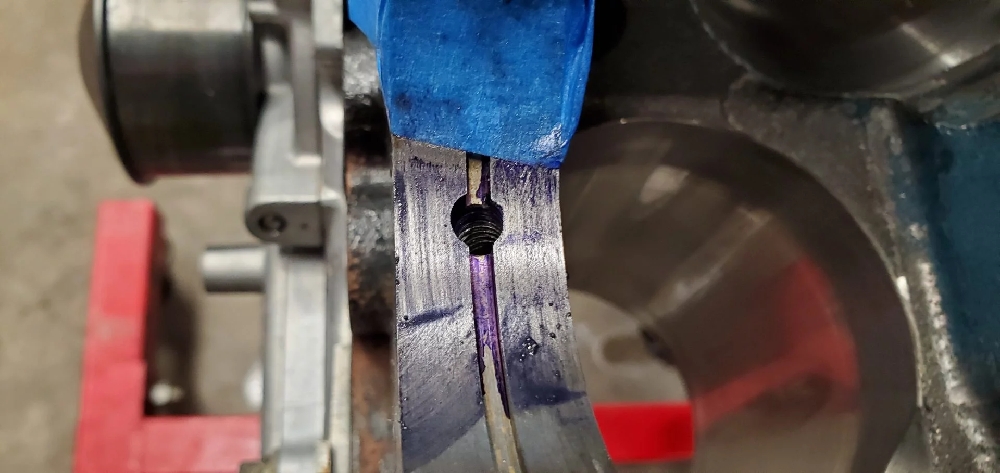

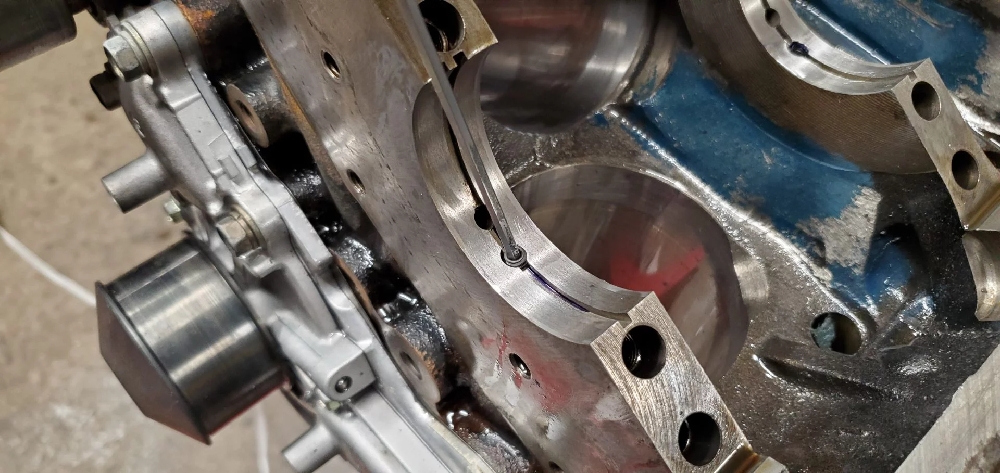

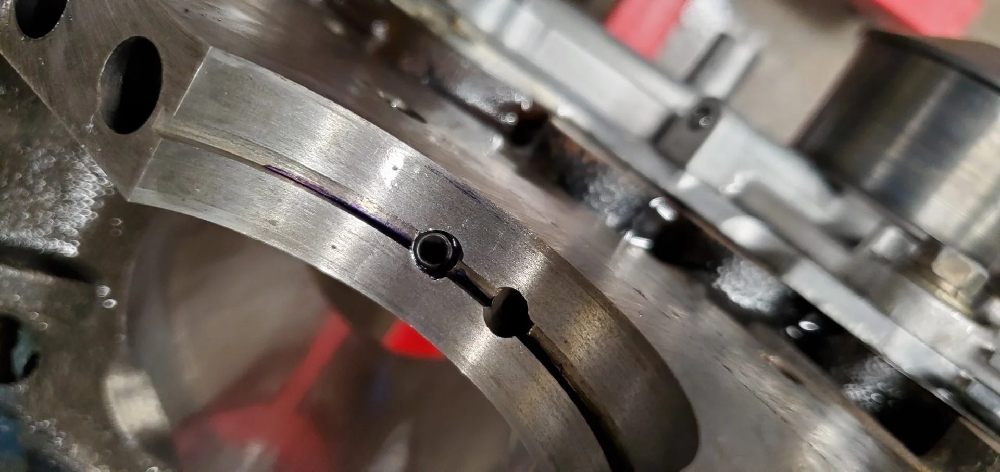

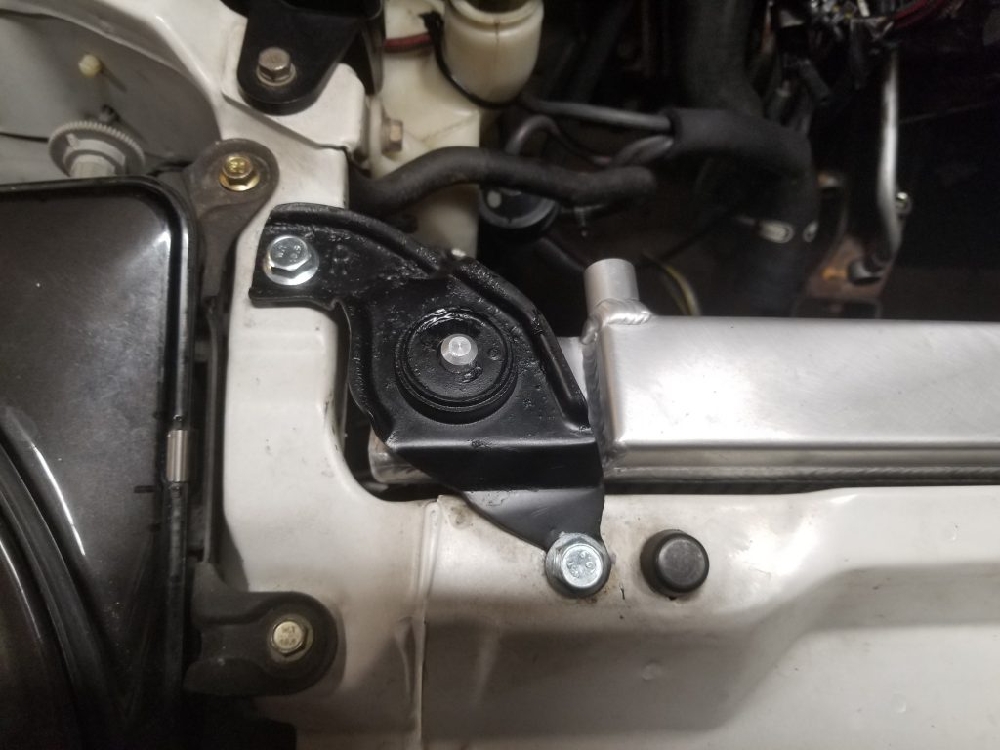

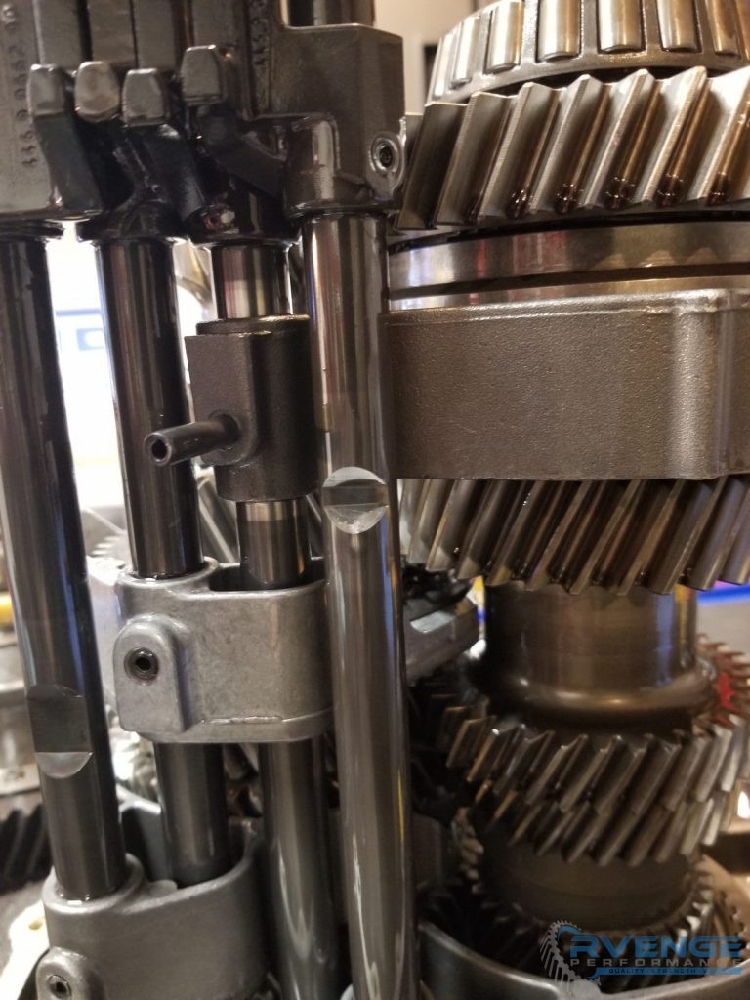

Fuel Injector Wiring Resistor Bypass 01.jpg)

Fuel Injector Wiring Resistor Bypass 02.jpg)

Fuel Injector Wiring Resistor Bypass 03.jpg)

Fuel Injector Wiring Resistor Bypass 04.jpg)

Fuel Injector Wiring Resistor Bypass 05.jpg)

Fuel Injector Wiring Resistor Bypass 06.jpg)

Fuel Injector Wiring Resistor Bypass 07.jpg)

Fuel Injector Wiring Resistor Bypass 08.jpg)

Fuel Injector Wiring Resistor Bypass 09.jpg)

Fuel Injector Wiring Resistor Bypass 10.jpg)

Fuel Injector Wiring Resistor Bypass 11.jpg)

Fuel Injector Wiring Resistor Bypass 12.jpg)

Fuel Injector Wiring Resistor Bypass 13.jpg)

Fuel Injector Wiring Resistor Bypass 14.jpg)

Fuel Injector Wiring Resistor Bypass 15.jpg)

Fuel Injector Wiring Resistor Bypass 16.jpg)

Fuel Injector Wiring Resistor Bypass 17.jpg)